2-piece Heat Induction Sealing Liners

Induction sealing is the process of bonding thermoplastic materials by induction sealing. This effect is widely use in the packaging industry for the sealing of containers with foil liners (IHS liners). The closure is supplied with a liner already inserted, which is quite convenient for fillers.

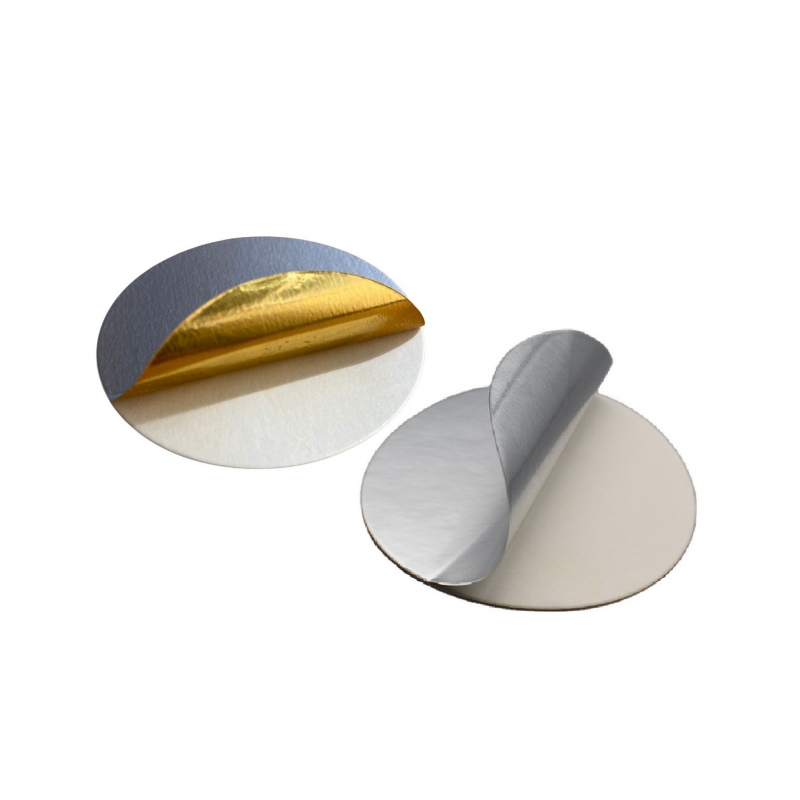

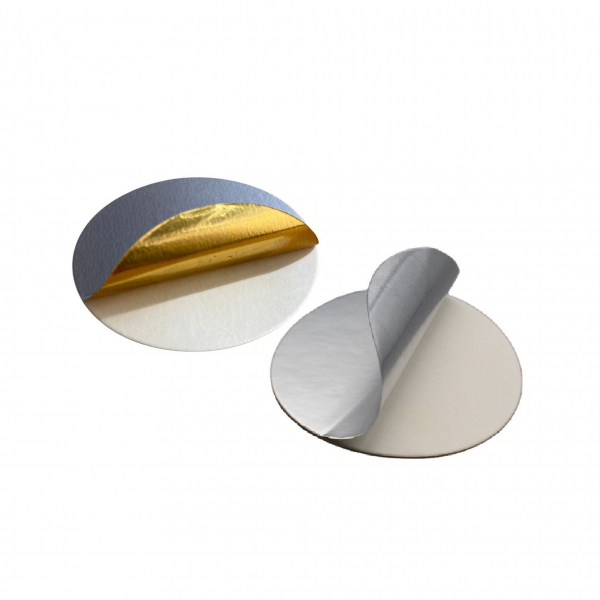

A typical induction liner is multi-layered and consists of three main components: backing material, aluminum foil and heat-sealing layer.

When 2-piece liner is used, the backing is separated from the foil and remains in the cap. This type of liners are more readily used when a product needs to be resealed once the container has been opened. It is especially useful when content is a liquid.

Backing material differs depending on the particular requirements – usually it is pulp board or EPE. Polymer waxes used for the sealing layer may be specific for glass, PET or HDPE. Some special solutions are available for the separation layer that bonds foil and the backing, the foil may have additional lamination layer.

Particular requirement dictate a choice, but pulp board backed liners with a standard sealing layer for PET or glass are the most common.

2-piece HIS liners may also have pulling tab folded under the backing, however, this option is obviously more expensive.

The foil in 2-piece liners is usually golden or silver. There is a possibility of a customer’s print on the foil; contact our managers for details, if interested.

-

Your inquiry cart

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)